Contact

Book service

Follow us

Sign up for our newsletter to receive our latest news and innovation updates.

See how Ellepot has helped growers all over the world do things smarter. Below you will find our library of client stories, best cases and articles, a wide number of brochures dedicated to pot & bedding cultures.

Because Ellepots are made from degradable paper, they function as natural containers that eliminate the need for traditional plastic pots. This unique design minimizes transplant shock, ensuring faster and more uniform rooting. By choosing Ellepot, you and your customers benefit from a viable, plastic-reduced solution that delivers stronger, more consistent plants and a more streamlined production flow.

With the Ellepots we get the good start

A customised Ellepot FlexAIR system has helped Alkemade reach their desired productivity goals and given their plants the ideal ‘good start’ – securing reliability in the production with high uniformity and high performance in the plants.

Ferbuary 23, 2023

SAVING 50,000 MILLION POUNDS OF PLASTIC

Knox Nursery annually produces 150 million young plants and 6 million 4-inch annuals. Knox said his company started to become serious about sustainability when it determined it could help its customers resolve the problem of what to do with empty plastic pots.

Dec 11, 2020

Speed Challenge

See how landscapers in US are testing how easily you plant with the Ellepot - saves time and money.

January 10, 2020

With Ellepot, production costs have been lowered significantly due to better and smarter handling & logistics.

The introduction of the Ellepot system has dramatically improved Hasfarm’s product quality of carnation cuttings.

The recently delivered NGL machine can operate at up to 28,000 Ellepots per hour with full row filling, and 20,000 per hour with the new zigzag pattern that allows for a lower plant density. This is over twice the maximum rate possible with the older semi-automatic machines already in use by Vitrofora.

Rooting of cuttings is fast, and plant quality is excellent. Good air movement between the Ellepots in the trays is a valuable feature, making drying out easy when this is needed.

The introduction of the Ellepot machines – with an estimated return of investment of four years - has improved Psenner’s product quality and saved up to 50 percent of labour costs per year.

The Ellepot system was something to become really enthusiastic about as the benefits for using it are important: saving on labour costs and an improving product quality.

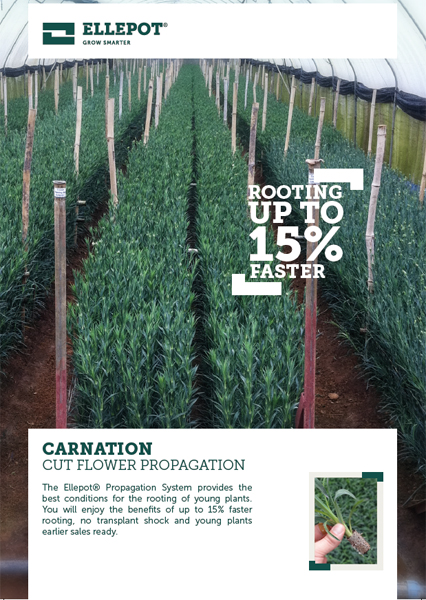

You will enjoy the benefits of up to 15% faster rooting, no transplant shock and young plants earlier sales ready.

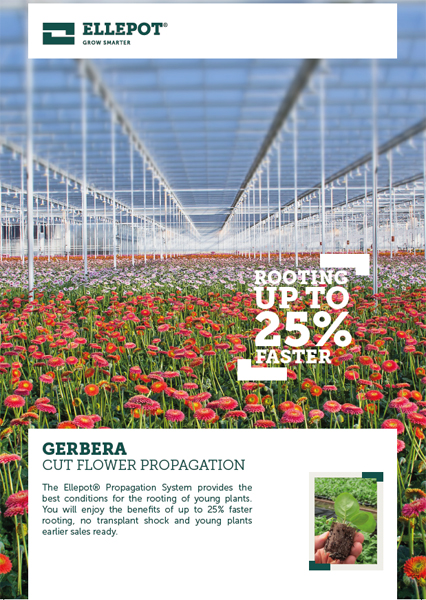

You will enjoy the benefits of up to 25% faster rooting, no transplant shock and young plants earlier sales ready.